BMS Board

Our BMS

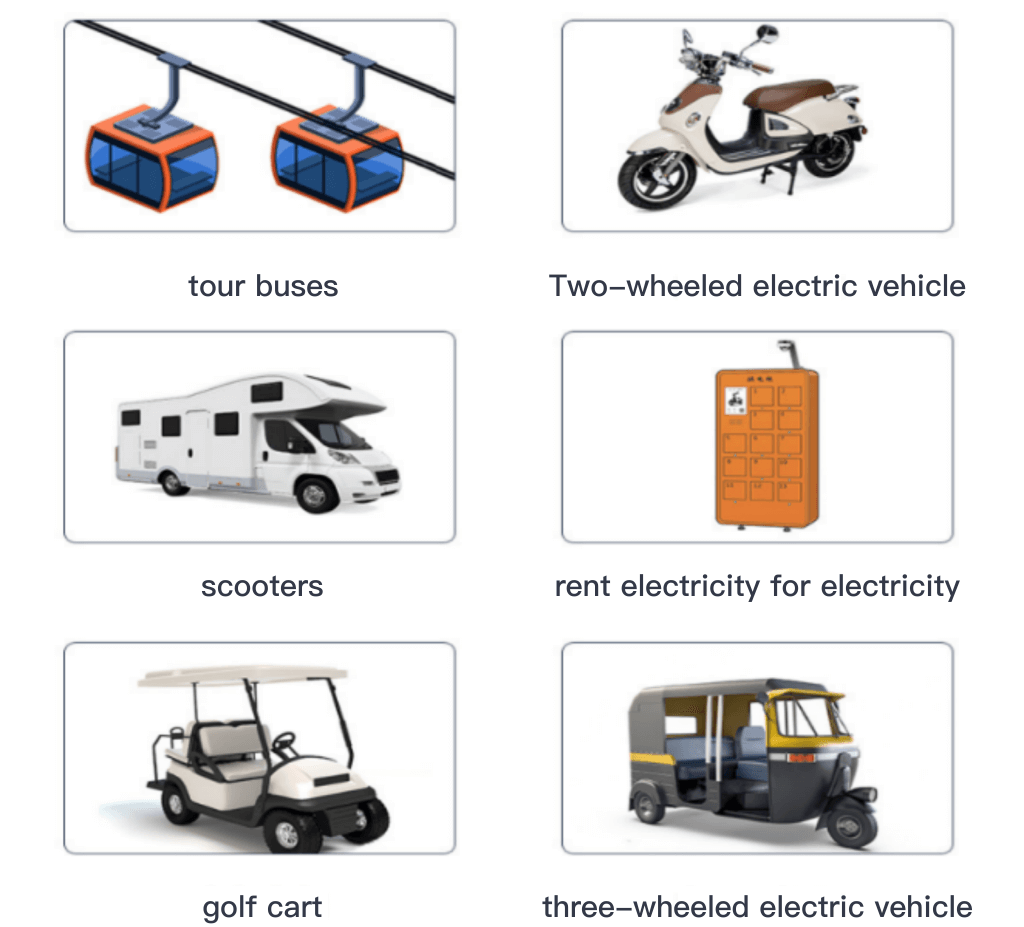

The lithium battery protection system (BMS) in the battery pack is an indispensable module in the electric bicycle two wheel electric vehicle, three wheel electric vehicle, electric motorcycle, electric scooter and other products. The common BMS board is used for the battery status: such as the balance, monitoring and protection of voltage, current, temperature, etc. At the same time, the battery status information is reported to the central control system of the electric vehicle.

In addition to the conventional hardware function monitoring and protection, ARay's new intelligent BMS software protection board is embedded with battery monitoring and protection+programmable control chip. Through UART/RS485/CAN three communication methods, it connects with the upper computer or touch screen, mobile phone APP, and intelligently manages the lithium battery. The multi-directional data monitoring and safety warning of battery current and voltage provide a complete dual protection of software and hardware for the entire lithium battery system of two wheel/three wheel electric vehicles, which greatly improves the safety performance.

Features

- 1. BMS for Lead acid replacement

- 2. BMS for 2 wheelers&3 wheelers/AGV

- 3. BMS for high speed motorcycle

- 4. BMS for golfcart/forklift/4 wheelers

- 5. BMS for battery swapping

Scope of application

Technical Parameter

| Functional Index Items | Recommended setting parameters | Remarkd | ||

|---|---|---|---|---|

| Holiday protectio (single battery) | ||||

| Single-section overcharge protection pile | Ternary 4.25V/FeLi 3.65V | 3.0V~4.5V, can be set software control, can be set 3.0V~4.5V | ||

| Single cell overcharge protection delay time | 1.0S, can be set | |||

| Single cell overcharge protection release voltage | Ternary 4.15V/FeLi 3.5V | |||

| Single cell overcharge protection released | When the monomer voltage drops to the recovery point, it will automatically recover | |||

| Over discharge protection (single battery) | ||||

| Single-section over-discharge protection pile | Ternary 2.75V/FeLi 2.5V | can be set,after over-discharge protection, enter the low power consumption mode when the monomer voltage is less than 2.1V ad the ternary voltage is less than 2.5V | ||

| Single-cell over-discharge delay time | 1.0S, can be set | |||

| Single-cell over-discharge protection release voltage | Ternary 3.0V/FeLi 2.9V | |||

| Recovery mode of over-discharge protection | Connect to the charger | |||

| Overall overcharge protection | ||||

| Overall overcharge protection voltage | Ternary battery strings * 4.25V Number of iron lithium battery strings*3.6V | software control can be set | ||

| Overall overcharge protection delay time | 1.0S, can be set | |||

| Overall overcharge protection released | ||||

| Overall over-discharge protection release voltage | Ternary battery strings * 4.0V Number of iron lithium battery strings*3.5V | |||

| Overall overcharge protection released | when the overall voltage drops to the recovery point, it will automatically recover | |||

| Overall over-discharge protection | ||||

| Overall over-discharge protection voltage | Ternary battery strings * 2.8V Number of iron lithium battery strings*2.5V | can be set, after over-discharge protection, enter the low power consumption mode when the monomer voltage is less than 2.1V and the ternary voltage is less than 2.5V | ||

| Overall over-discharge protection delay time | 1.0S, can be set | |||

| Overall over-discharge protection released | ||||

| Overall over-discharge protection release voltage | Ternary battery strings * 3.1V Number of iron lithium battery strings*2.9V | |||

| Charge release | Connect to the charger | |||

| Short ocircuit protection | ||||

| Short circuit protection current | 20000+-20% | A | ||

| Short circuit protection delay time | 200 | 600 | 800 | US |

| Short circuit protection release method | Disconnect the load; in view of the short-circuit current of thousands of amps, to avoid danger, it is not recommended for customers to do a short-circuit test | |||